Livestock and poultry manure centralized treatment farms or organic fertilizer production enterprises will use special vehicles to regularly recycle livestock and poultry manure to each farm to avoid secondary pollution on the road surface and directly transfer the recovered livestock and poultry manure into the fermentation area.

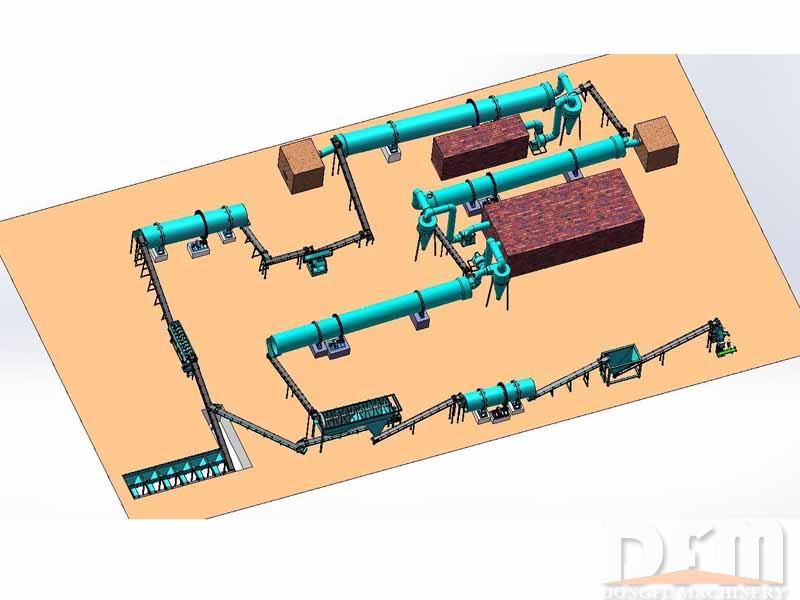

After fermentation, Firstly, the odor of livestock and poultry manure is eliminated. During the fermentation, straw, plant leaves, weed powder and other plant stems should be added in proportion. At the same time, the fermenting bacteria should be added, and the crude fiber therein should be decomposed so that the particle size requirement after crushing meets the particle size requirement of the granulation production. The fermentation finished material is pulverized and enters the mixing and stirring system. Before mixing, according to the formula, N, P, K and some other trace elements are added to the mixing system, and then transported into the granulation system, such as disc granulation system, granules enter the cooling system after passing through the dryer, and the material will be sieved under normal temperature, and the granules that meet the requirements will be packaged after entering the coating machine to wrap the coating film. And the unqualified granules will be crushed by a crusher again, and returned to the disc granulation system to continue granulation. After several procedures, livestock and poultry manure became the main raw material of organic fertilizer and entered the sales market for direct sales.

DFM Fertilizer Machine, supply you with the best quality of organic fertilizer production machines & best service!!

For more information about the organic production line, click here please.

Contact: DFM Fertilizer Machine

Phone: +86-13663722676

E-mail: andy@zzdfm.com

Add: No. 37 Yuxiang Road, High Tech Zone, Zhengzhou City, Henan, China