Organic fertilizer processing and production technology: livestock and poultry manure centralized treatment plants or organic fertilizer production enterprises will use special vehicles to collect livestock and poultry manures at various farms to avoid secondary pollution to the road and pavement, and the recovered livestock and poultry manures will be directly entered Fermentation area. The whole process shall pass through primary fermentation, secondary aging and stacking. First, the odor of livestock and poultry manure is eliminated. During the fermentation, straw, plant leaves, weed powder and other plant stems and leaves should be added in proportion. At the same time, fermentation bacteria should be added to decompose the crude fiber in it, so that the particle size after crushing meets the particle size requirements of granulation production. The fermentation material powder system that has completed the secondary aging and stacking process is granulated and enters the cooling system after passing through the dryer. The material is brought to room temperature and then sieved. The granules that meet the requirements enter the coating machine to wrap the coating film and start packaging. The granules that do not meet the requirements are crushed by the pulverizer and then returned to the disc granulation system to continue granulation. After the above procedures, the animal manure becomes the main raw material of organic fertilizer and enters the sales market for direct sales.

The organic fertilizer processing and production process generally includes: raw material selection (chicken manure, straw, sludge, grass charcoal, etc.), fermentation treatment, ingredient mixing, granulation, cooling and screening, metering and sealing, and finished product storage. The latest standard of organic fertilizer: powder or granular (3-4 mm) Quality standard: refer to the national implementation standard of organic fertilizer NY525-2011. Water content 30%, organic matter 45%, total nutrients (nitrogen, phosphorus and potassium)> 5%, pH value shall be 5.8-8.5.

The production process of chicken manure organic fertilizer is: organic fertilizer raw materials (animal manure, domestic garbage, dead branches and leaves, biogas residue, waste bacteria, etc.) are fermented into a semi-wet material pulverizer for crushing, and then nitrogen, phosphorus, and potassium(pure nitrogen, phosphorus pentoxide, potassium chloride, ammonium chloride, etc.) are added, to make the contained mineral elements reach the required standard, then there is a mixer to stir, and then enter the granulation mechanism to granules, after they come out, they are dried and passed through a sieving machine. The qualified products are packaged, and the unqualified products are returned to the granulator for granulation.

Among them, the reasonable mix of the fineness of the raw materials is very important for the organic fertilizer production process. The higher the fineness of the raw material, the better the viscosity and the higher the surface finish of the granulated particles. However, in the production process, the use of excessively high-fineness materials is prone to problems such as excessively large particles and irregular particles due to excessive viscosity.

Organic fertilizer, with livestock manure, domestic waste, and plant straw as the main raw materials, the production process of this organic fertilizer is roughly as follows: raw material drying-crushing-fermentation-blending (mixed with chemical fertilizers and other organic-inorganic substances to make nitrogen + phosphorus + Potassium content>4%, organic>30%)

Crop stalks: Crop stalks are one of the important fertilizer varieties. Crop stalks contain essential nutrients for crops such as N, P, K, Ca, S and so on. Cake fertilizer: rapeseed cake, cotton seed cake, bean cake, sesame cake, castor bean cake, tea seed cake, etc. Mud: unpolluted river mud, pond mud, ditch mud, harbor mud, lake mud, etc.

For example, if the raw material is humic acid or grass charcoal, there is no fermentation in this organic fertilizer production process, and the remaining steps of fermentation are not required to be composed of the mixing system, granulation system, screening system and finished product packaging system.

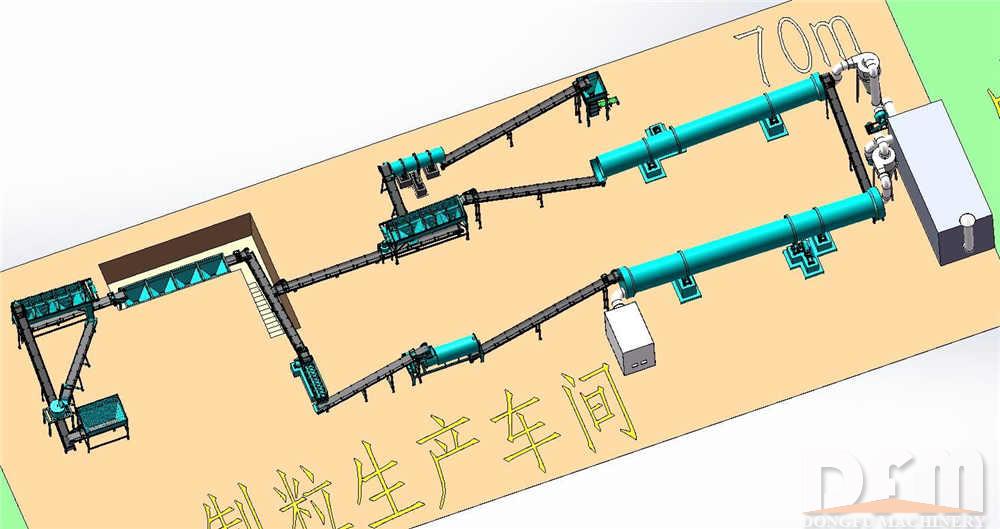

The construction scale of the equipment configuration of the chicken manure organic fertilizer production line is generally 5,000 to 100,000 tons per year. It is necessary to comprehensively consider local resources, market capacity, and market coverage. 1. The investment scale and product plan design need to be formulated based on the following conditions: the characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, and comprehensive consideration of local resources, market capacity, and market coverage radius. In general, small new plants can produce 10,000 tons (1.5-2.5 tons/hour), 20,000 tons (2.5-3.5 tons/hour), and 30,000 tons (4.5-6 tons/hour) per year. Medium-sized factories are producing 3 -50,000 tons, large factories are producing 50,000-100,000 tons per year. The investment scale and product plan design need to be formulated according to the characteristics of raw material resources, local soil conditions, local planting structure and main crop varieties, factory site conditions, and the degree of automation of production.

Organic fertilizer can be divided into powdery organic fertilizer and granular organic fertilizer in the production process of organic fertilizer. Among them, the powdery organic fertilizer process is relatively simple: detecting the ingredients of your raw materials (such as plant ash, furfural residue, humic acid, etc.), knowing the accurate nutrients and nutrient ratios in each raw material plays an important role in the organic fertilizer production process. ; The general production process of organic fertilizer requires that the content of nitrogen, phosphorus and potassium exceed 4% and the organic matter exceeds 30%. If you are satisfied with this organic fertilizer production process, it can be mixed, crushed and packaged.

Granular organic fertilizer requires equipment, such as wet-process organic fertilizer granulator, drum granulator, organic fertilizer granulator or disc granulation or double-roll extrusion granulation. The production process of organic fertilizer requires that the raw materials are basically the same as powdered fertilizer, but after adding a binder (bentonite or attapulgite), the finished particles need to be dried by a tumble dryer.

The above is just to introduce some simple and general organic fertilizer production process. For detailed information, DFM Fertilizer Machine wholeheartedly provides users with various compound fertilizer and organic fertilizer processing and production equipment and technical consulting services. The main products: organic fertilizer production line, chicken Manure organic fertilizer equipment, organic fertilizer production equipment, compound fertilizer complete equipment, BB fertilizer processing equipment, granulator, organic fertilizer granulator, disc granulator, roller extrusion granulator, organic fertilizer dryer , Bio-organic fertilizer grinder, organic fertilizer fermentation turner, roller screening machine, mixer, conveyor and other equipment.

DFM Fertilizer Machine specializes in manufacturing and installing complete sets of organic fertilizer production line equipment, organic fertilizer production process, organic fertilizer raw material ratio, organic fertilizer formula and other one-stop services, so that you can invest in peace of mind.

DFM Fertilizer Machine: All products sold by our company are guaranteed for half a year! DFM Fertilizer Machine pave your way to entrepreneurship with the most attentive service!

Contact: DFM Fertilizer Machine

Phone: +86-13663722676

E-mail: andy@zzdfm.com

Add: No. 37 Yuxiang Road, High Tech Zone, Zhengzhou City, Henan, China